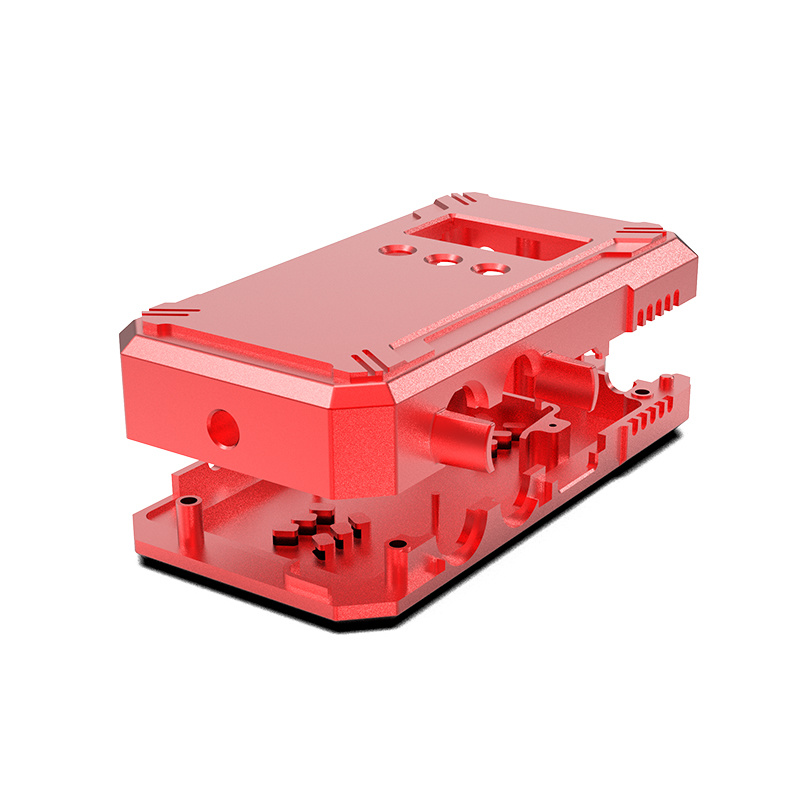

CNC Vehicle Lithium Powerbank Enclosure 124L77W28H

SIZE (W*H)

124mm x 77mm x 28mm

|

Customization |

Custom Size |

| Custom logo • Engraving • Laser Printing • Silk Screen Printing • UV Printing |

Custom Components • Screw • Stud • Bolts • Liner • Handle • Wrap Angle • Other |

|

Custom Cutouts Such as hole for: |

Custom Color • Other |

-

Colour

-

Black

Black

-

Gray

Gray

-

Blue

Blue

-

Golden

Golden

-

Pink

Pink

-

Red

Red

-

Purple

Purple

-

Green

Green

-

Yellow

Yellow

-

Customizd color card

Customizd color card

-

- Product Description

- parameter

-

The CNC Battery Enclosure is a battery enclosure manufactured using computer numerical control (CNC) machining technology, offering numerous unique advantages in battery protection and application.

1. High-Precision Manufacturing

Precision Fit

CNC machining technology achieves extremely high precision. For battery enclosures, this means custom processing based on the exact dimensions of the battery, ensuring a tight fit. Whether it's a prismatic, cylindrical, or even a uniquely shaped battery, the CNC Battery Enclosure achieves a near-perfect fit, effectively preventing movement within the enclosure and enhancing battery safety.

Precise Interfaces

For interfaces where the battery connects to external devices, CNC machining can precisely create interface holes, slots, and other structures. For example, when rechargeable batteries are used in electronic products, precise interface design ensures stable charging and data transmission, avoiding issues caused by mismatched interfaces or poor contact.

2. High-Quality Material Protection

Excellent Sealing

The CNC Battery Enclosure is designed with a well-sealed structure, which is crucial for protecting the battery from external environmental influences. It effectively blocks dust, moisture, and other impurities from entering the battery, preventing short circuits or damage from moisture. This sealing property can significantly extend the battery life, especially for batteries used in harsh environments, such as those in outdoor equipment.

Mechanical Protection

As the battery's external protective structure, the CNC Battery Enclosure possesses a certain degree of mechanical strength. It can withstand minor external impacts, such as impacts and pressure, protecting the battery cells, circuitry, and other components within the battery from damage. This mechanical protection reduces the risk of damage during transportation, installation, and daily use.

3. Appearance and Customization

Aesthetic Diversity

CNC machining enables the creation of a variety of aesthetically pleasing designs. Intricate textures, patterns, or smooth surface finishes can be created on the surface of the enclosure. This aesthetically pleasing design enhances the overall aesthetics and user experience of battery enclosures in consumer electronics.

Customized Design

Different battery applications have different requirements, and the CNC Battery Enclosure can be customized to meet specific customer requirements. Whether in terms of enclosure shape, size, color, or functional structure, we can meet individual customization needs. For example, a battery enclosure customized for specific industrial equipment might require additional heat dissipation structures or specialized markings, all of which can be easily accomplished through CNC machining.

With its high precision, excellent protection, and customization, CNC battery enclosures play an indispensable role in numerous battery applications.

-

Customization

• No MOQ Limited

• Custom Sample Shipping 7-10 DaysCustom Size

• Length/Width/Height/Thickness could be customized flexibleCustom logo

• Engraving

• Laser Printing

• Silk Screen Printing

• UV PrintingCustom Components

• Screw

• Stud

• Bolts

• Liner

• Handle

• Wrap Angle

• OtherCustom Cutouts

• Hole CNC MillingSuch as hole for:

• LAN

• Led or other display

• Fan exhaust

• Power jack

• Oled

• OtherCustom Color

• Black

• Silver

• Grey

• Blue

• Red

• Gold

• Yellow

• Brown• Other

• Via Anodizing/Powder Coating

Product inquiry

Have a question about purchasing a product or solution that you are interested in? Fill in the form and we’ll respond in 7 working days.