Product Category

About us

Shenzhen Shengyuanda Hardware Products Co., Ltd. (cyd) was established in 2011 as a professional manufacturing enterprise specializing in aluminum alloy enclosures, sheet metal fabrication, and CNC machining services. With over a decade of experience in precision manufacturing, cyd provide tailor-made solutions for our clients in industries such as electronics, telecommunications, automotive, and more.

cyd, located in Shenzhen, covers an area of more than 5,000 square meters and is supported by a dedicated team of more than 120 employees, of which 30% are technical professionals. Equipped with advanced machinery such as CNC machining centers, bending machines, punching machines, welding equipment, laser machines, and advanced testing tools, we ensure the efficient and precise production of every product.

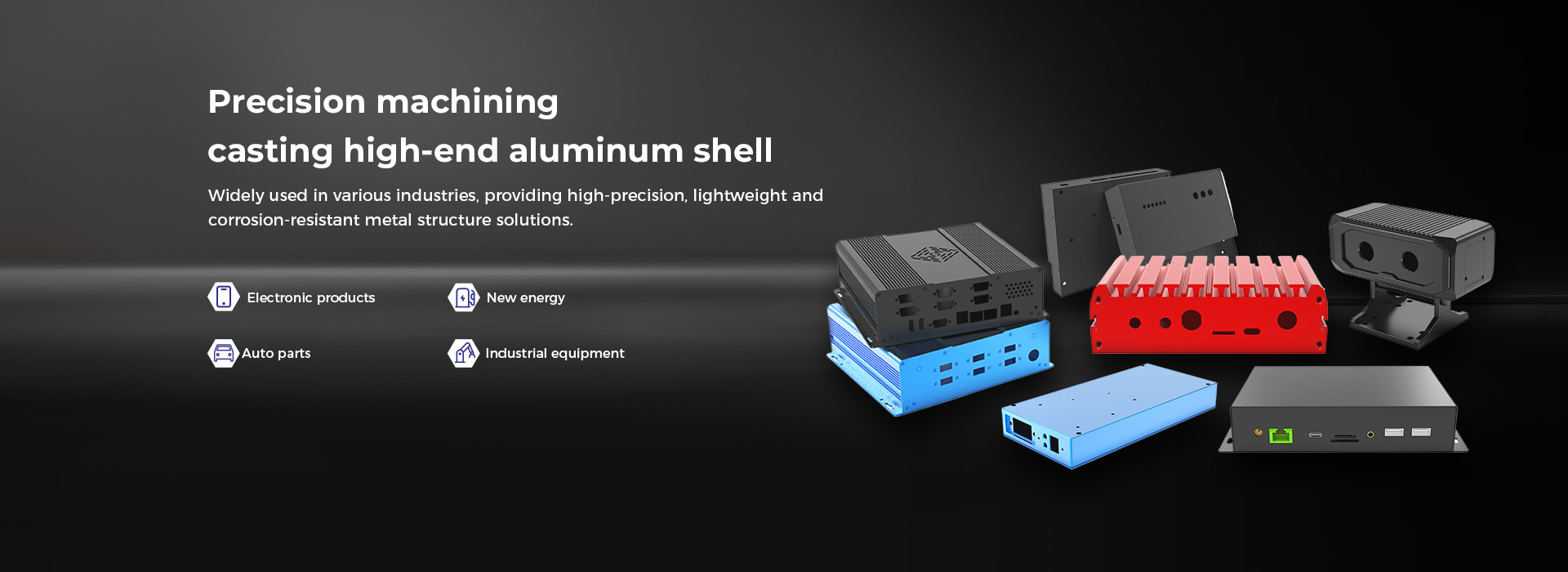

Application

Three Production Processes

Aluminum Profile Enclosure

01

Cutting

02

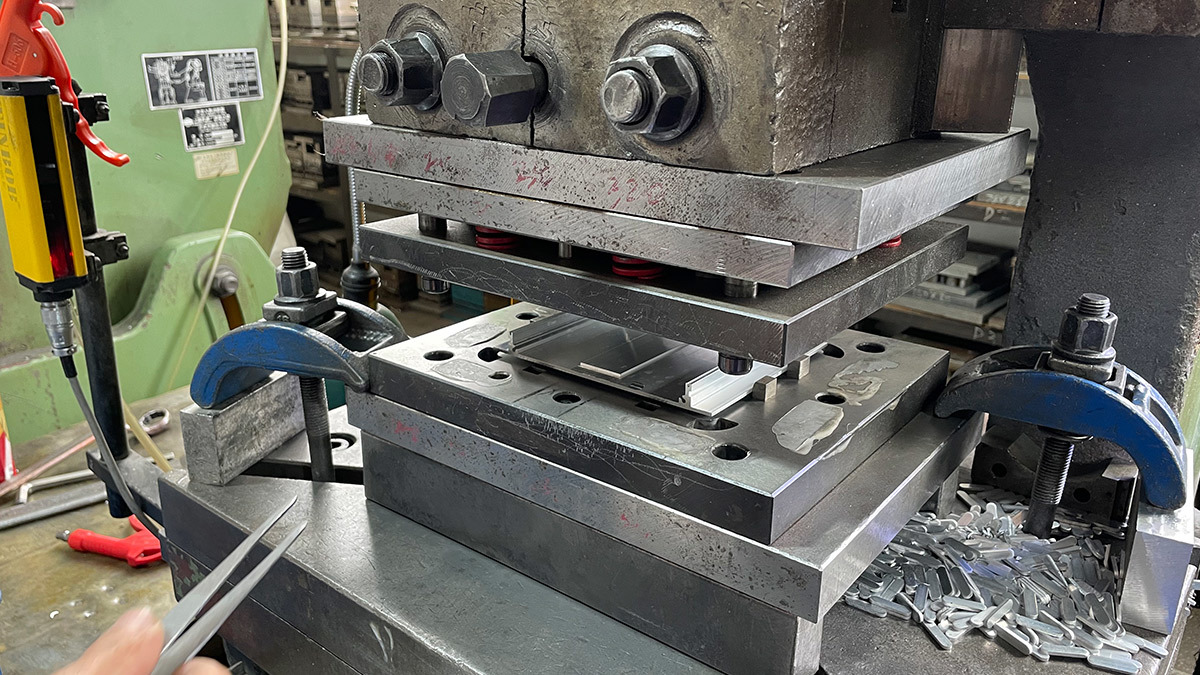

Stamping

03

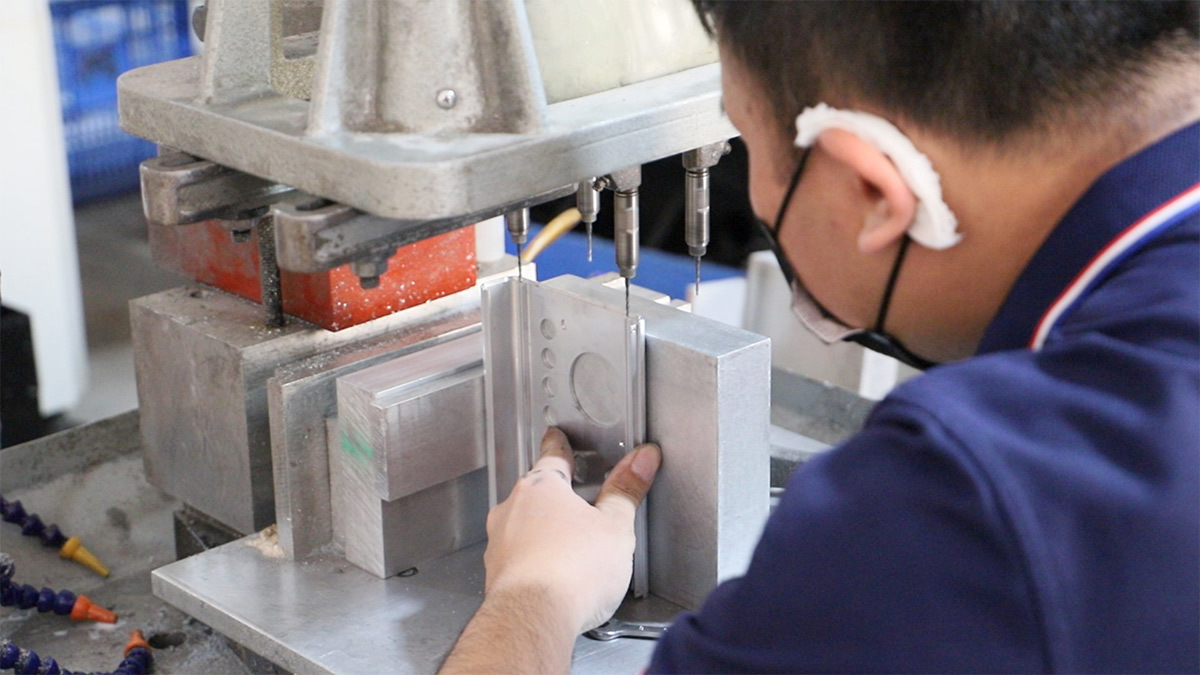

Tapping

04

Polishing

05

Anodizing

06

Screen Printing

07

QC and Packing

08

Delivery

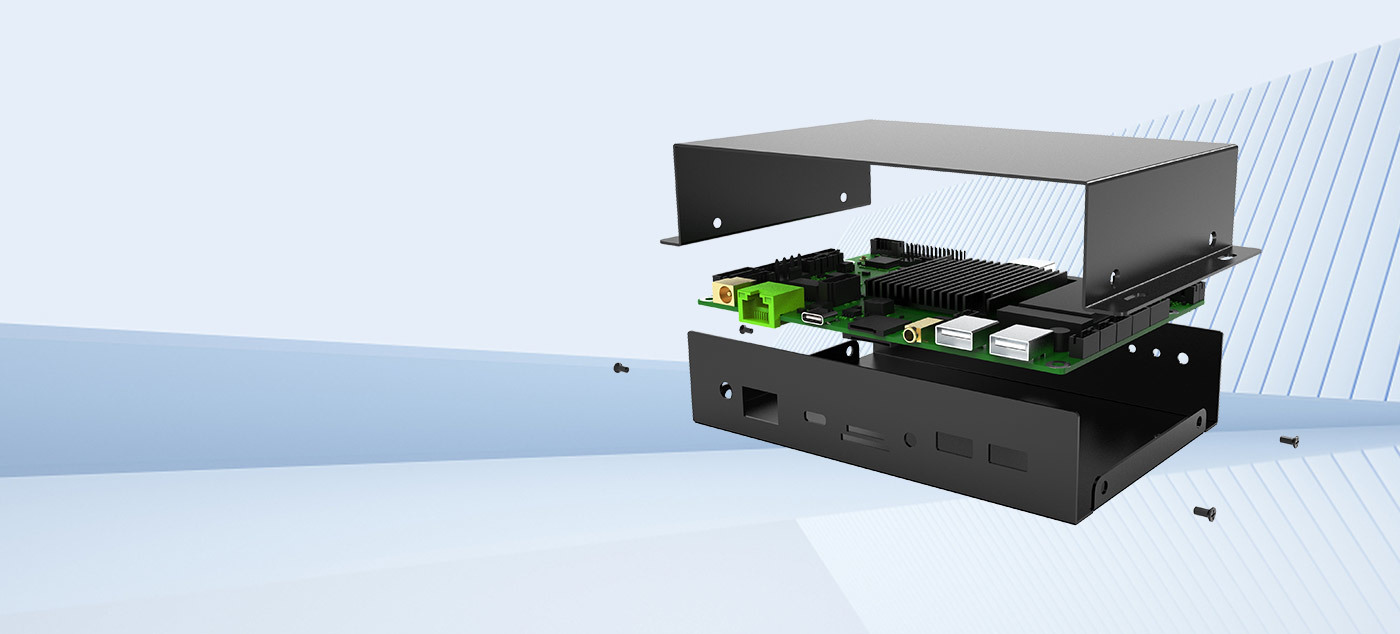

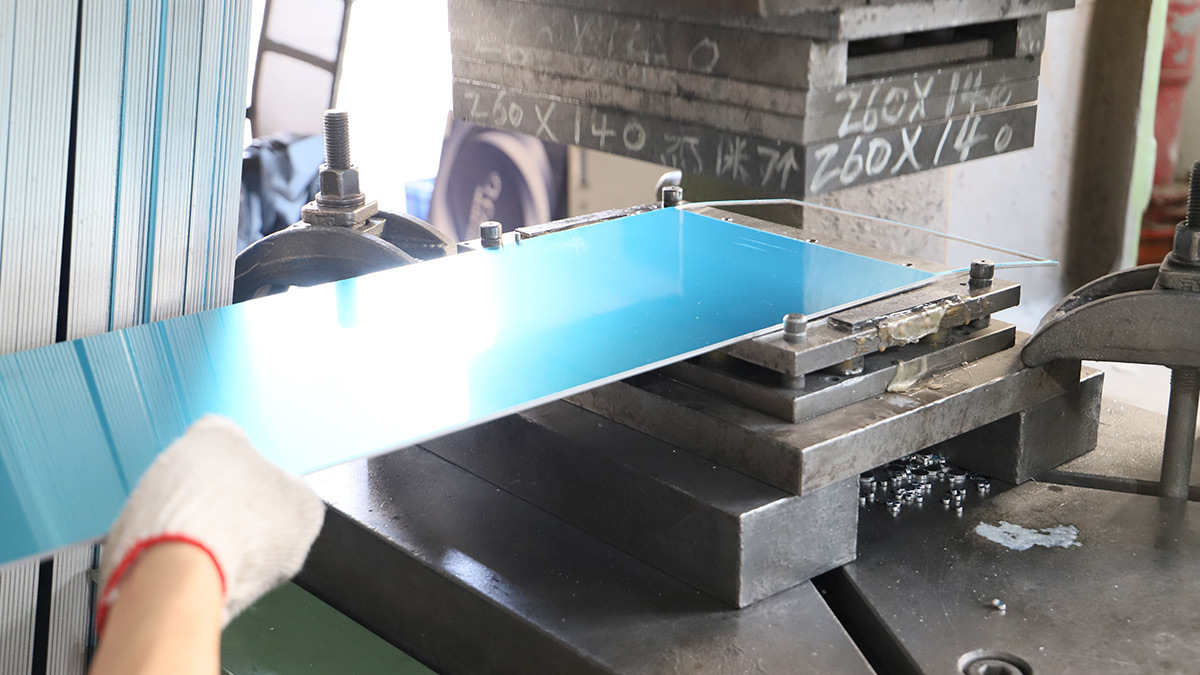

Sheet Metal Enclosure

01

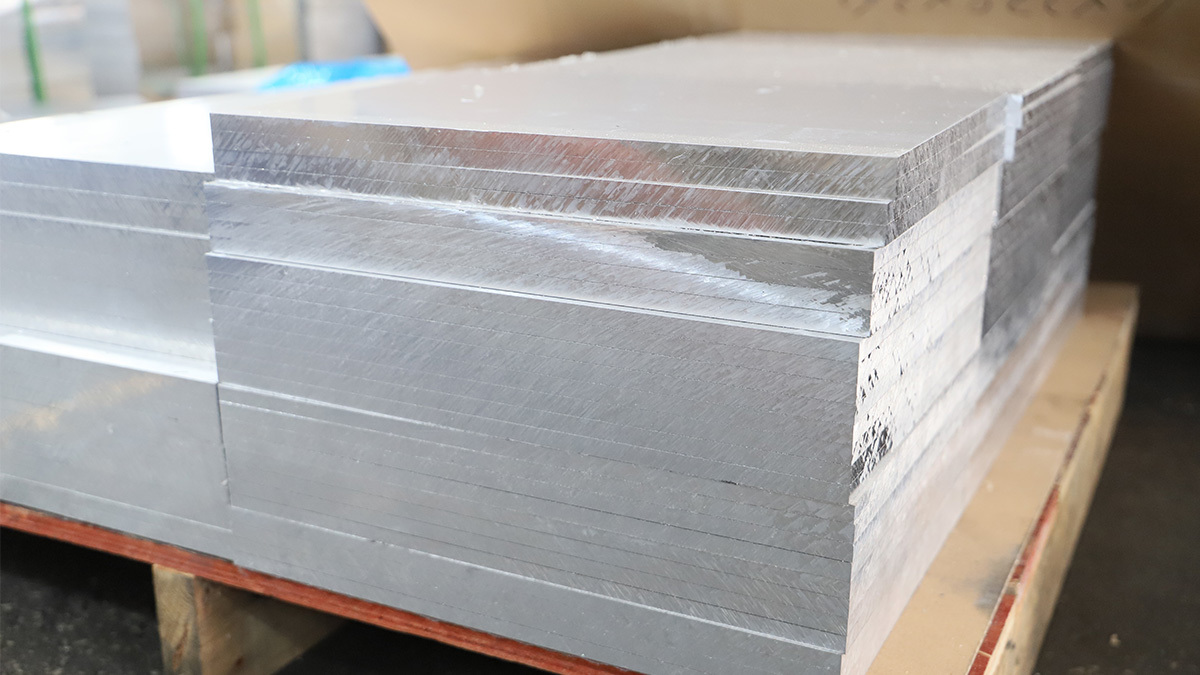

Raw Material

02

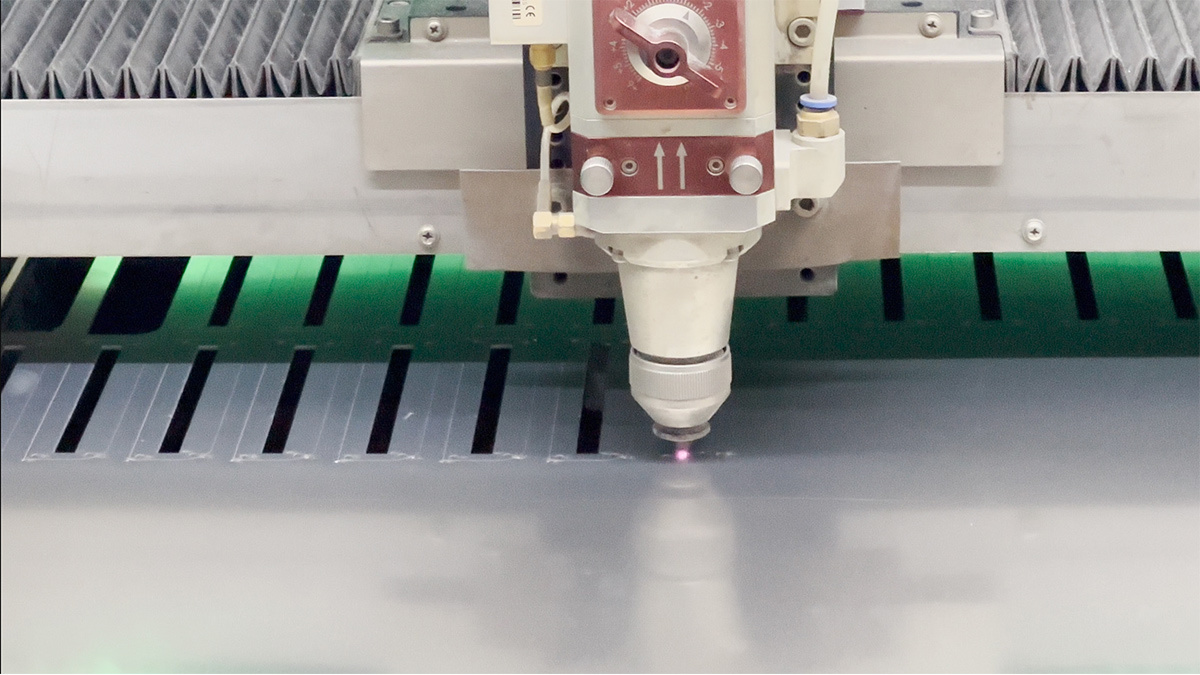

Laser Cutting

03

Bending

04

Stamping

05

Riveting

06

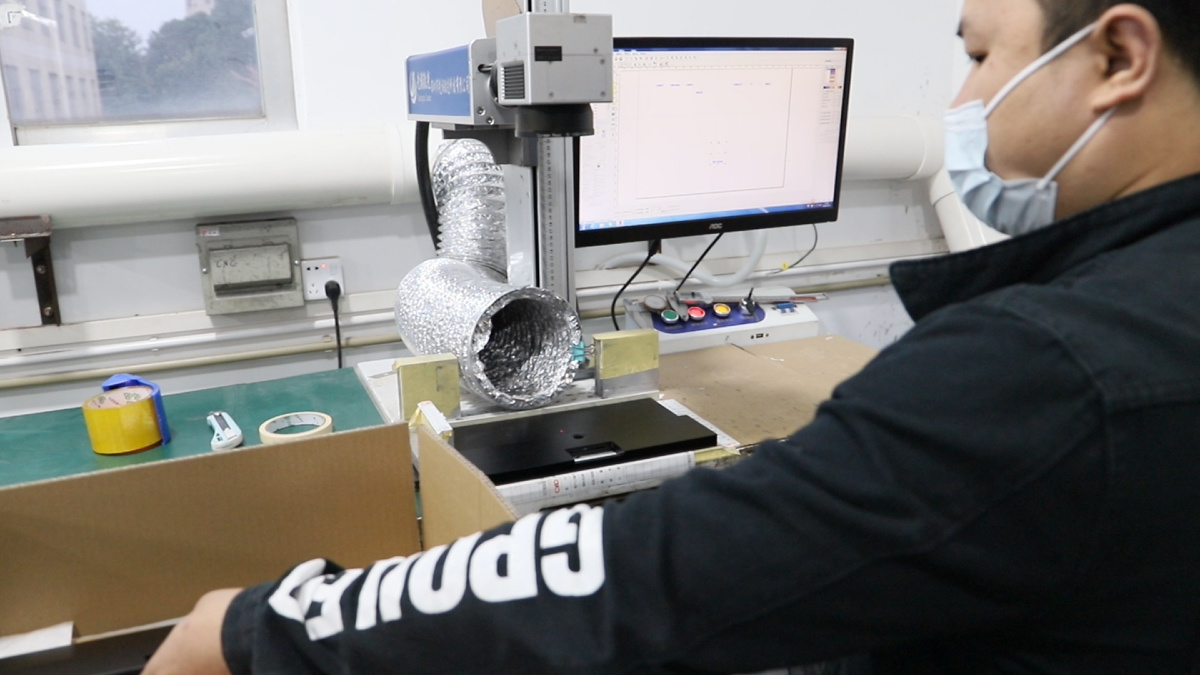

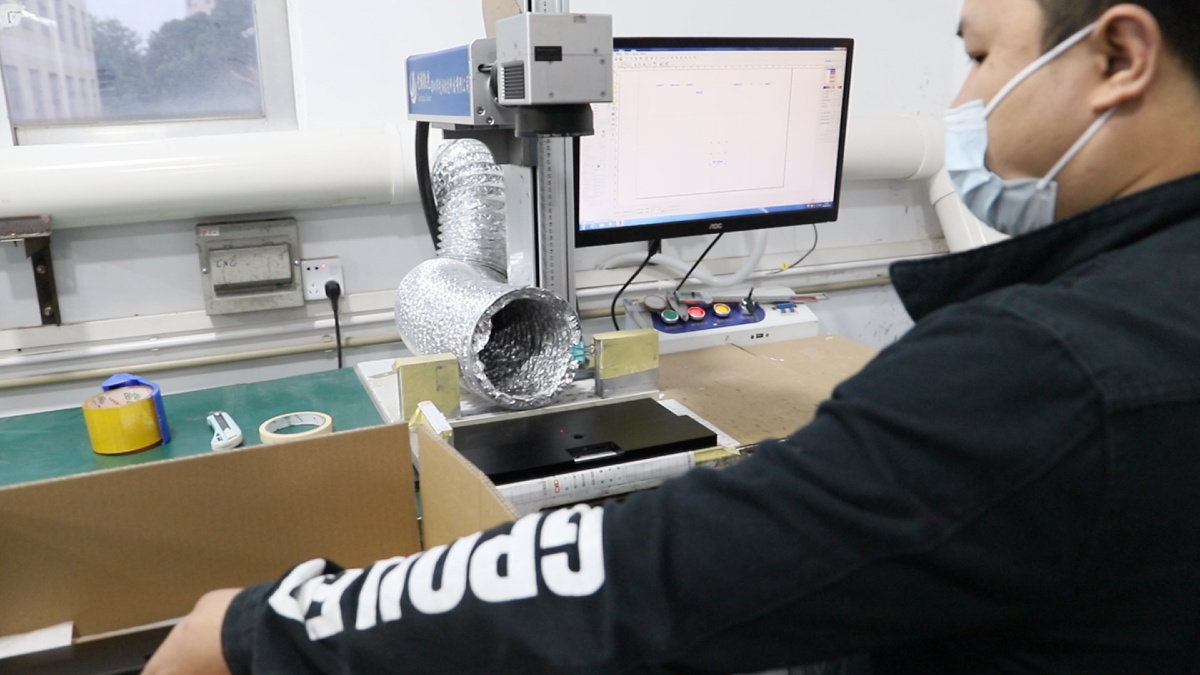

Laser Carving

07

QC and Packing

08

Delivery

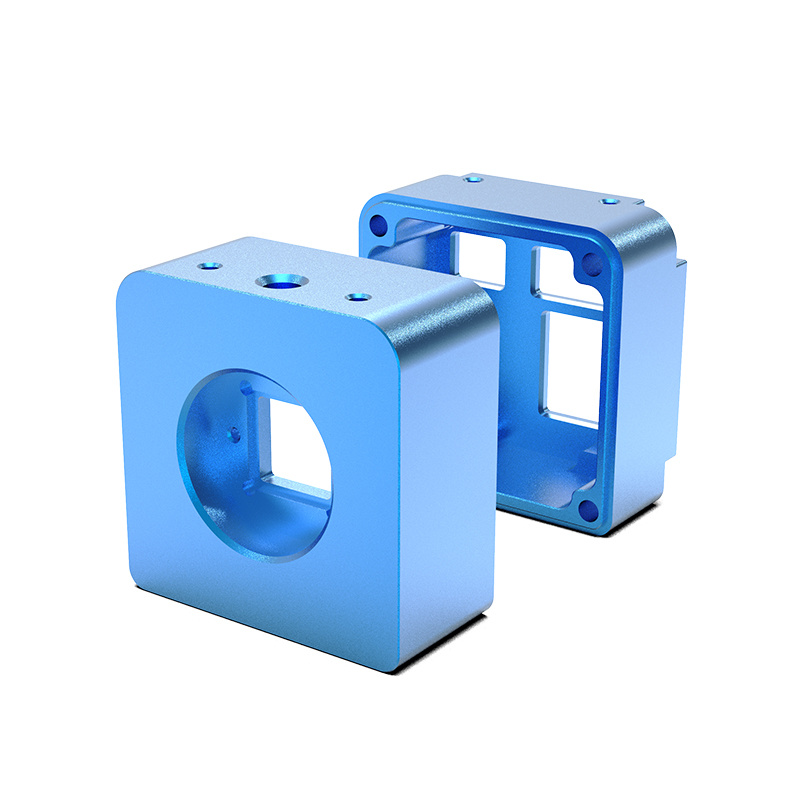

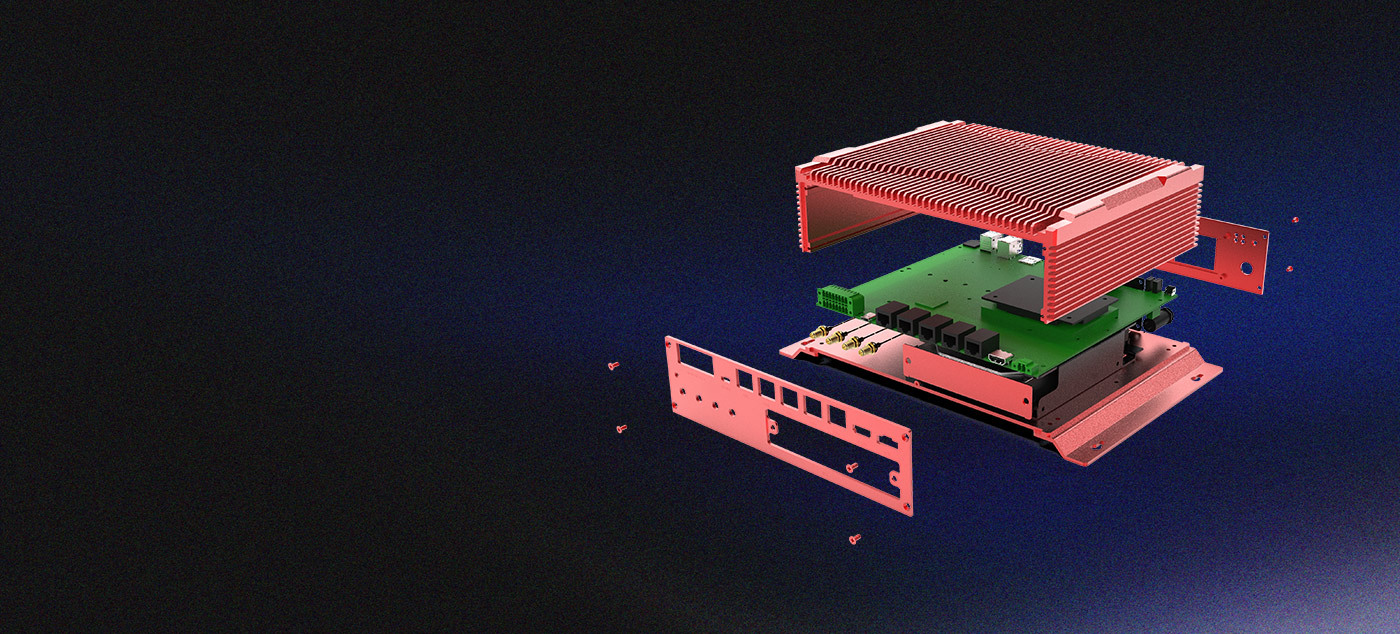

CNC Machining Service

01

Programming

02

Raw Material

03

CNC Machining

04

Product Testing

05

Surface Treatment

06

Laser Carving

07

QC and Packing

08

Delivery

Quality Inspection

Company Video

Featured Products

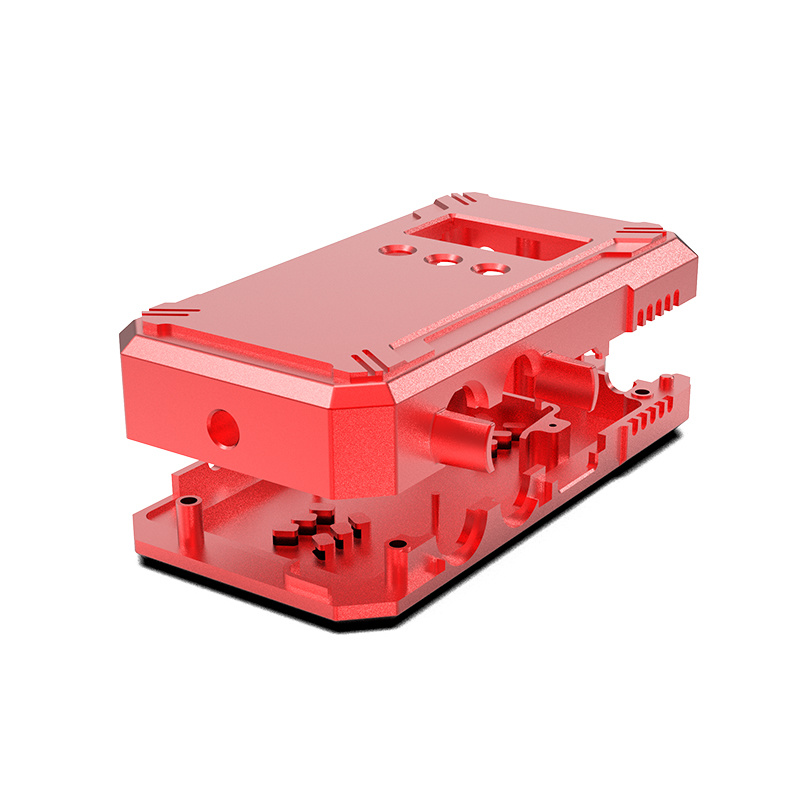

117mm x 40mm x 29mm, CNC parts

CNC Parts 117L40W29H

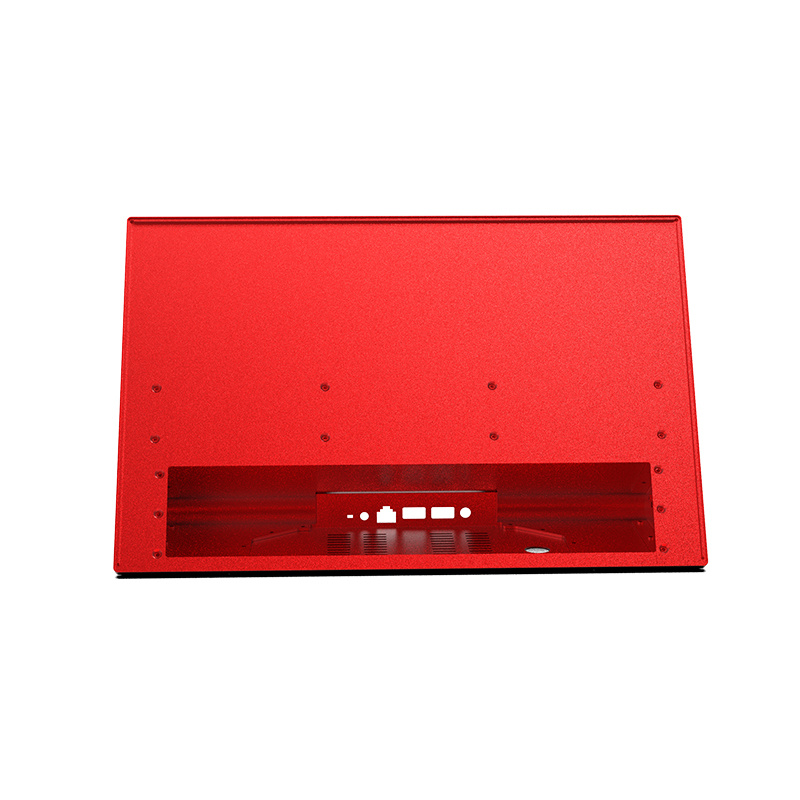

356mm x 233mm x 104mm,Portable Display

CNC LCD Portable Display Enclosure 356L233W104H

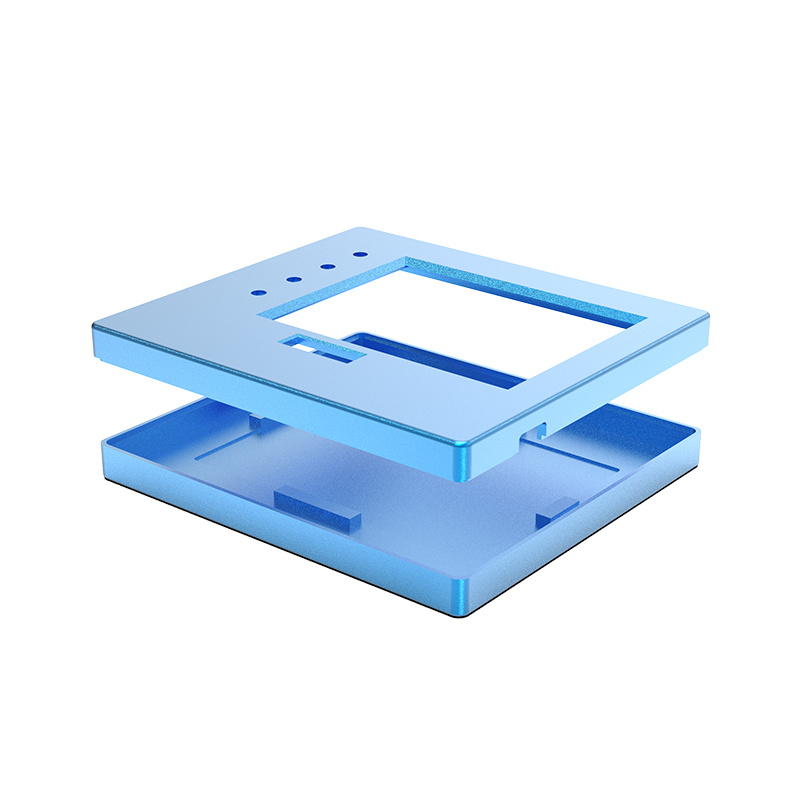

200mm x 100mm x 20mm,Docking Station

CNC Docking Station Enclosure 200L100W20H

145mm x 70mm x 20mm,Power Supply,Battery

CNC Power Supply Housing Battery Enclosure 145L70W20H

Customization Sequence

Submit CAD Files to Us via Email or TM

You can send 2D or 3D files along withdetailed information (such as material,quantity, tolerance, etc.) to us via emailor TradeManager.

Manufacturing Feasibility Analysis and Quotation Offer

Secondly, we will analyze themanufacturability based on the productdrawings and provide you with acompetitive quotation.

Go to production!

Thirdly, we will begin the manufacturingprocess once all relevant details arefully confirmed.

Parts inspection completed goods shipped

Finally, we will carefully package andship the goods once the products arecompleted.

Partners

Contact Us

Get our latest offers and news straight in your inbox

Blog

Our Advantages

From mold design to surface treatment One-stop manufacturer

15 years of professional aluminum deep machining manufacturer

5000+ customers have recognized the quality of the product, Received mostly positive reviews from customers

Monthly production of 2 million pieces Guaranteed quality and quantity, zero delays

100% inspection of finished products, Quality rate of shipment is as high as 99%